PROFINET Manual

In a PROFINET IO-System the following devices may be differentiated:

Symbol |

Name |

Meaning |

|

IO-Controller |

One IO-Controller is always in charge of the IO-System. Typically this is a PLC or PC based controller. |

|

IO-Device |

One or several IO-Devices are controlled by the IO-Controller in the IO-System. This are typically field devices with interfaces to the physical world as sensors or actuators. |

|

IO-Supervisor |

The Engineering Tool (ET) has access to the IO-System as an IO-Supervisor. One or several IO-Supervisors may optionally be connected to an IO-System. They can communicate with all members of the IO-System. |

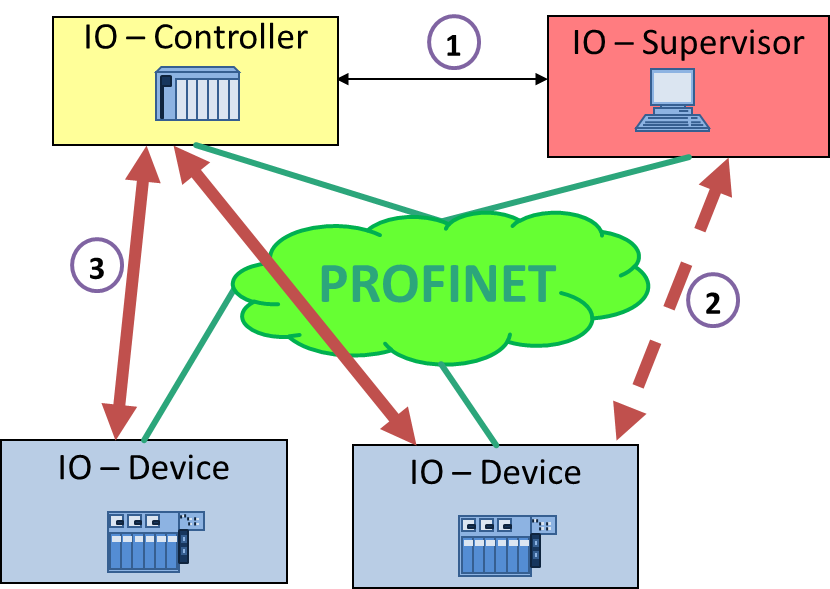

There are different Application Relation (AR) between the different stations in a IO-System. These AR have a different functionality and goal (see legend of the figure). Relation 1 is not define in the PROFINET standards and specific to the manufacturer of the IO-Controller.

Figure 17: Three relations between stations.

1. Application Relation (AR) for the control of the process

2. Distribution of names and other parameters

3. Download configuration from the Engineering Tool (ET) to the IO-Controller

For redundancy reasons it is possible to have more than one IO-Controller in the same IO-System. In this case all IO-Controller have to be planned, but only one at one moment in time is the primary controller and the other controller has to be the secondary standby controller.

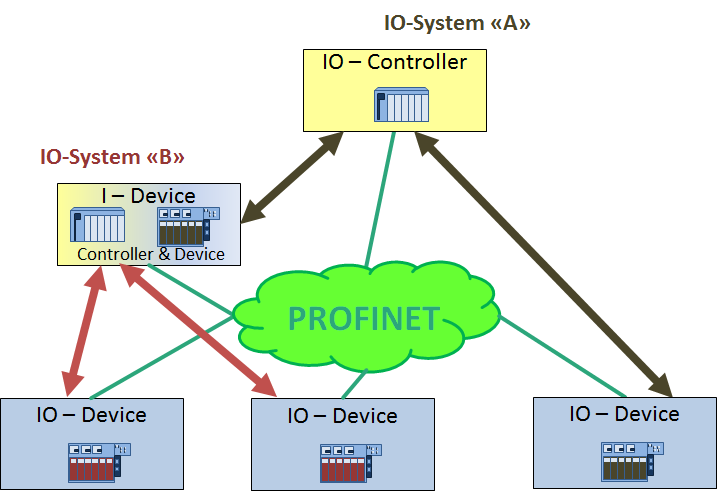

It is also possible to combine several IO-Systems in one network. This allows to define:

•shared IO-Devices = several IO-Controllers using subslots in the same IO-Device

•shared Inputs = several IO-Controllers reading the same input modules in one IO-Device

•I-Devices which are IO-Controller and IO-Device at the same time.

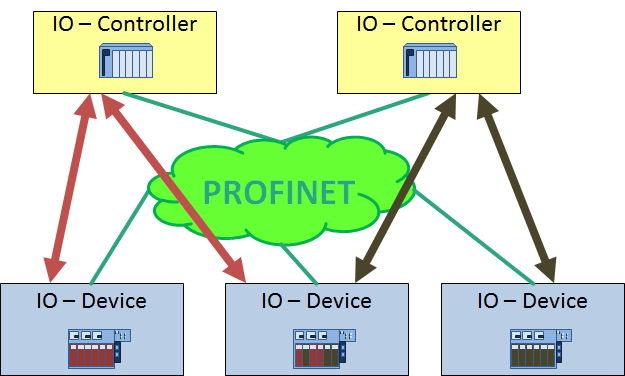

The shared device allows several IO-Controllers to access modules in slots or subslots on the same IO-Device

▪flexible assignment of modules (I/Os) from one IO-Device to different IO-Controllers.

▪One module is clearly assigned to only one IO-Controller.

Benefit:

▪simpler and more cost efficient setup of plants.

▪especially advantages in project where different profiles like PROFIsafe or PROFIdrive are used.

Figure 18: Shared IO-Device

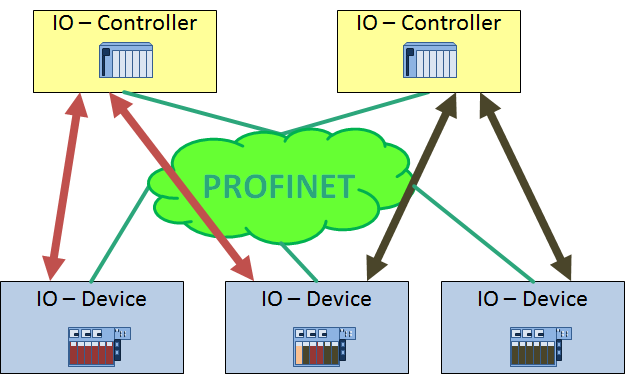

On a shared input several IO-Controller may use the same input data from one module of an IO-Device

•flexible assignment of input modules (only inputs! NO outputs) from one IO-Device to different IO-Controllers.

Benefit:

▪simple sharing of sensor values

▪more cost efficient setup of plants.

Figure 19: Shared input

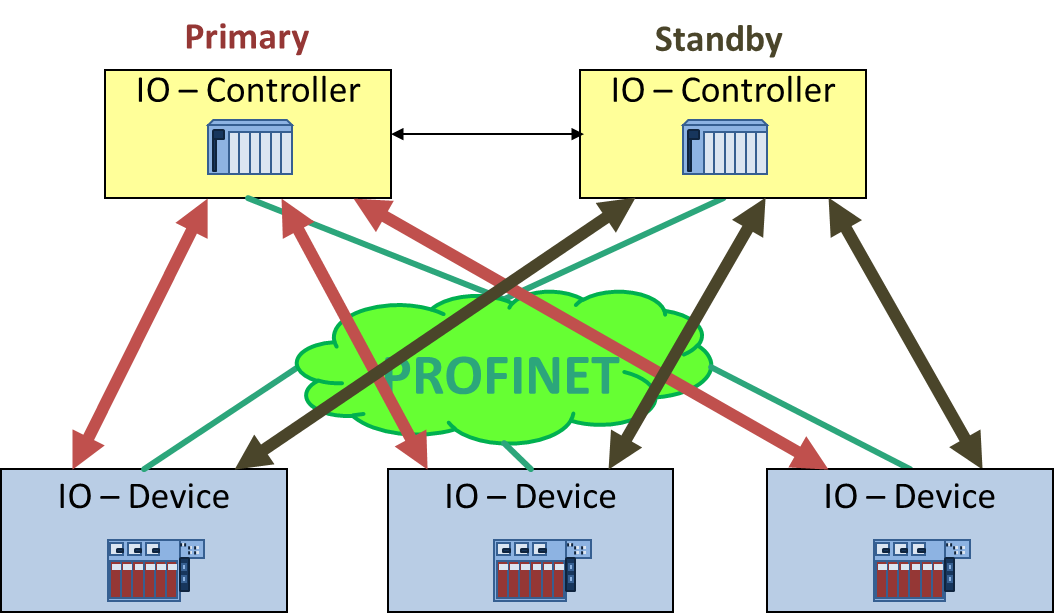

A redundant IO-Controller improves the system availability. Both IO-Controller use the same configuration, but one is the primary controller and the other is the standby controller. Both controllers establish the AR to all IO-Devices. The IO-Device sends cyclic the input data to both controllers, but takes action only on the cyclic output data of the primary controller. The output data of the standby controller is ignored by the IO-Device.

Figure 20: Two IO-Controller may be connected to one IO-Device for redundancy

An Intelligent Device (I-Device) can be an IO-Device and IO-Controller at the same time. This allows to build hierarchical IO-Systems or even coordination functionality between controllers.

Figure 21: I-Device is IO-Device and IO-Controller at the same time